The Essential 5: Must-Have Power Tools for a Small Woodworking Shop

Running a small woodworking shop is a delicate balance between **space, budget, and efficiency**. Every machine you bring in must earn its spot by delivering accuracy, versatility, and long-term durability. The good news is you don’t need a warehouse full of heavy-duty equipment to produce professional-quality work. With the right foundational setup, you can confidently tackle everything from custom furniture builds to intricate cabinetry without sacrificing time or floor space.

We’ve curated the **five most essential power tools** that form the backbone of a successful small-scale operation. These tools are the workhorses that provide the biggest return on your investment.

The Core Five: Power Tools That Drive Small Woodworking Shop Success

1. The Table Saw: The Heart of the Shop

If you can only invest in one major power tool, make it a high-quality **table saw**. It is the undisputed workhorse, capable of ripping sheet goods, cross-cutting lumber, cutting tenons, and even doing careful joinery. The quality and accuracy of your cuts determine the quality of your finished product, and no other tool does this better.

What to Look For in a Small Shop:

- Portability/Size: A contractor-style saw integrated with a sturdy stand or a compact cabinet saw is ideal.

- Fence System: This is critical. Look for a robust fence that locks square and remains accurate. A precision fence dramatically increases safety and cut quality.

- Dust Collection Port: Essential for connecting to your dust system (see #5) to keep your workspace cleaner and safer.

- Blade Quality: A premium blade makes all the difference. Pair your saw with high-end blades (like those from **Freud** or **Amana Tool**) for smooth, burn-free cuts.

- Safety Features: Consider models with advanced safety systems like **SawStop**, which stops the blade upon contact with skin, making them the safest saws in the world.

2. Router and Router Table: Ingenuity in a Small Package

No shop is complete without a **router**. Whether used freehand or mounted in a router table, routers excel at shaping edges, cutting complex joinery (like dadoes and rabbets), and forming decorative molding. A high-quality mid-sized router ($2.25$ HP) offers the perfect balance of power and maneuverability.

Maximizing Router Versatility:

- Router Table Setup: Pairing your router with a small, dedicated router table instantly converts it into a versatile joint-making, profiling, and edge-shaping machine.

- Variable Speed Control: Look for a model with variable speed to safely handle bits of different diameters and materials.

- Interchangeable Bases: A plunge base and a fixed base offer the most flexibility for different operations.

3. Sliding Compound Miter Saw: Quick and Precise Crosscuts

For quickly and accurately cutting long boards to length, nothing beats a **sliding compound miter saw**. It’s a massive time-saver for breaking down stock, cutting precise corners for frames, or handling crown moulding pieces. The sliding feature allows for much wider crosscuts than a standard miter saw.

Key Features to Seek Out:

- Sliding Rails: Necessary for wide crosscuts (up to 12 or 16 inches).

- Positive Stops: Ensure there are reliable positive stops for common angles like $0^\circ, 45^\circ$, and $22.5^\circ$.

- Space-Saving Design: Consider a model with front-mounted rails or one that can be mounted against a wall to conserve precious floor space.

Pro Tip: Reserve your table saw for final, precision-dimensioning cuts. Let the miter saw handle the rougher dimensioning cuts; this extends your table saw blade’s lifetime and keeps it sharp for critical work.

4. Cordless Drill/Driver and Impact Driver: Daily Necessities

In a small shop, you’ll reach for a cordless **drill/driver** and **impact driver** constantly—for assembling jigs, building cabinets, and installing hardware. Going wireless gives you maximum power and flexibility to move around your shop (or a job site) without wrestling with cords.

- Lithium-Ion Batteries: Ensure you have two or more high-capacity, long-lasting batteries.

- Impact Driver: The impact driver provides superior torque for driving long screws without tiring the user or stripping the screw heads.

- High-Quality Bits: Keep a range of sharp, high-quality brad point and twist drill bits on hand for clean, accurate holes in solid wood.

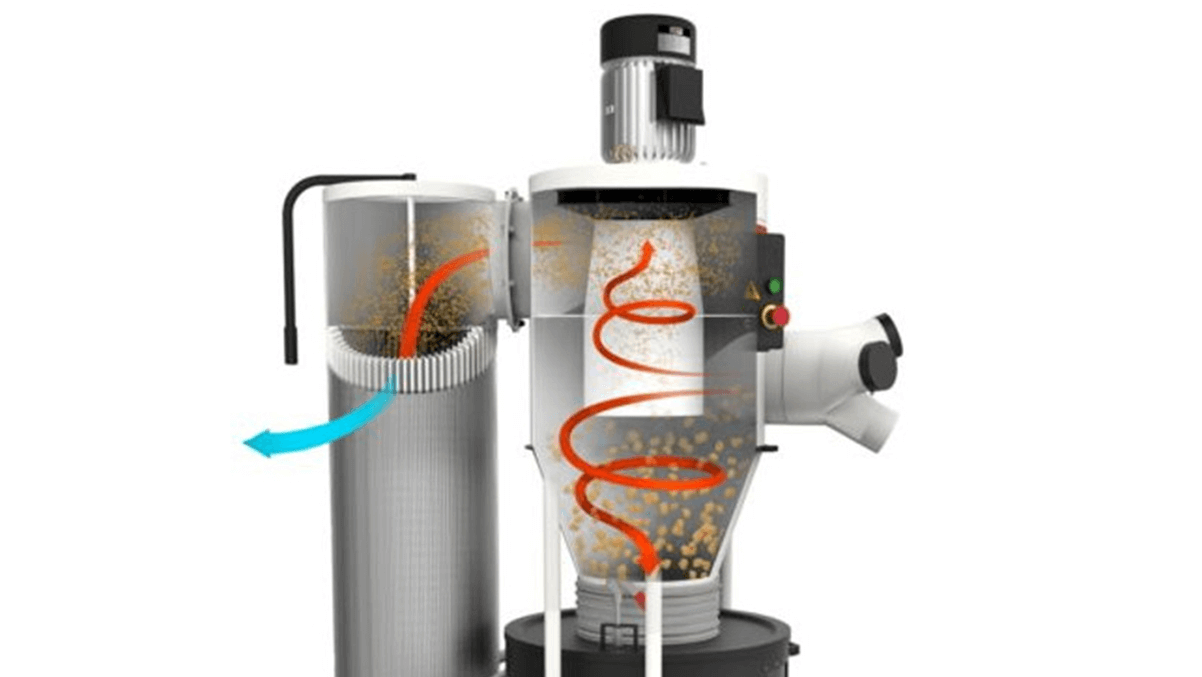

5. Dust Collection System: Don’t Skimp on Safety

While it may not seem like a “power tool,” a dedicated **dust collection system** is one of the most important investments you will make. Even a small shop requires a dedicated dust collector or a high-capacity shop vacuum (like the **Festool CT Midi** or similar). Wood dust is a serious health hazard and a fire risk.

Benefits of Good Dust Collection:

- Health & Safety: Cleans the air, providing a safer working environment for your lungs.

- Tool Longevity: Tools last longer and run cooler thanks to reduced dust and debris buildup.

- Efficiency: Less time spent cleaning at the end of the day.

Start simple with a mobile unit, or install a compact, wall-mounted system. Upgrade as your shop grows—your lungs and your tools will thank you.

The Essential Finisher: Random Orbital Sander

The joinery and cuts get all the attention, but the **finish** is what makes or breaks a project. A **random orbital sander** is the go-to tool for preparing wooden surfaces before applying stain, paint, or a topcoat. The random orbital motion prevents the dreaded “swirl marks” while removing material quickly and evenly.

- Professional Results: Ensures a glass-smooth surface ready for a flawless finish.

- Grit Range: Pair it with a variety of high-quality sanding discs (from 80-grit for aggressive removal up to 220-grit and higher for final smoothing).

- Integrated Dust Management: Choose a sander with excellent built-in dust collection or an outlet for your vacuum system.

Frequently Asked Questions (FAQ)

Which tool should I buy first?

If your budget is limited, the **Table Saw** should be your first major purchase. It is the most versatile tool and is necessary for accurate dimensioning of nearly all lumber and sheet goods.

Is a drill press necessary for a small shop?

While a drill press offers superior accuracy for repetitive or deep drilling, it is not essential for the “Core Five.” A quality **cordless drill/driver** is sufficient for most smaller shop needs. A drill press can be a smart addition after the core tools are acquired.

What is the most important maintenance tip for these tools?

The most important maintenance tip is to always use **sharp, high-quality blades and bits**. Sharp tools cut cleaner, more safely, and put less strain on the tool’s motor, extending its life. Regularly clean all tools and lubricate moving parts according to the manufacturer’s guidelines.

Further Resources and Reading

- Wood Magazine – Source for project plans, tool reviews, and woodworking techniques.

- Fine Woodworking – High-quality articles and videos on advanced techniques and tool setup.

- Tools Today – A major retailer of high-quality saw blades and router bits (Amana Tool).