CNC Carbon Fiber Cutting: Tips, Safety and Bits Selection

Carbon fiber is one of the most impressive materials you can make – it’s strong, lightweight and elegant. But it’s also one of the hardest. Anyone who has ever tried to cut on a CNC router knows that it can chew up small parts, wear down the edges, and fill your shop with dangerous dust if you’re not careful.

The good news: With the right preparation, protective gear, and… Compound router bits from Amana Tool®With it, you can produce clean edges and professional-quality results while keeping your equipment and lungs safe.

What is carbon fibre?

Carbon fiber is not a solid piece of carbon. It’s a compound They are made by weaving thin strands of carbon together and embedding them in a resin, usually epoxy. Once cured, it forms a hard layer that is incredibly light and extremely strong.

Because it is a composite, cutting carbon fiber is much like manufacturing layers of fabric and hardening glue simultaneously. The resin can melt or crack if heated too much, while the fibers can fray or disintegrate if cut incorrectly.

- The strength to weight ratio is very high

- Excellent hardness and fatigue resistance

- Heat and chemical resistance

- Conductive to electricity

Amana® Solid Carbide End Mill Diamond Pattern, Composite Cutting Router Bits

Amana® Solid Carbide End Mill Diamond Pattern, Composite Cutting Router Bits

Amana® Solid Carbide End Mill Diamond Pattern, Composite Cutting Router Bits

Amana® Solid Carbide End Mill Diamond Pattern, Composite Cutting Router BitsWhere carbon fiber is used

Carbon fiber anywhere shows strength and low weight:

- Cars and motorsport: Body panels, arches and instrument panels

- Aerospace and drones: Drone frames and internal components

- Navy: Propellers, hull reinforcements

- Sports gear: Bicycles, paddles and paddles

- Industrial and medical devices

- Custom project fabrication and fabrication

As CNC routers have become more capable, even small workshops have begun handling carbon fiber sheets for custom parts, prototypes, and technical builds.

Challenges of CNC carbon fiber machining

Carbon fiber is known to be abrasive. They wear down standard carbide bits at an alarming rate, resulting in jagged edges and airborne dust that is not only messy – but conductive and dangerous.

Key issues include:

- scrape: Quickly thins standard cutting tools

- Lamination: Layers can peel or wear if the feed rate or bit geometry is wrong

- Heat accumulation: It can burn or weaken the resin

- Dust hazards: Fine conductive carbon particles can damage electronics and lungs

That’s why it requires carbon fiber manufacturing Specialized compound cutting bits And strict safety precautions. Carbon fiber reinforced polymers (CFRP) require a highly wear-resistant carbide substrate, large grooves and an impact area that is not only limited to… "Shatter" Carbon fiber is solid but also keeps the heat down.

Safety first

Before cutting carbon fiber, make sure your shop setup protects you and your equipment.

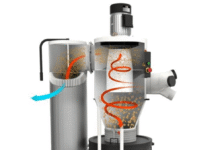

1. Dust collection

Use a complete dust collection system or vacuum tool directly at the cutting point. Carbon dust spreads easily and can short out CNC electronics if it settles inside the machine.

2. Respiratory system protection

A P100 respirator It is necessary. Regular dust masks will not stop ultrafine particles that are released during cutting.

3. Eye and skin protection

Wear safety goggles and sealed gloves. The fibers can irritate the skin and eyes if airborne.

4. Machine safety

Keep your CNC grounded, and avoid open electronic devices near the work area. Some mechanics use a light misting or “wet cutting” system to trap dust and keep the material cool.

10 Industrial Solid Carbide Router Bits for Carbon Fiber Reinforced Polymer (CFRP)

10 Industrial Solid Carbide Router Bits for Carbon Fiber Reinforced Polymer (CFRP)Select the correct router bits

Amana Tools® carbon graphite and carbon fiber solid carbide router bits are designed to produce minimal failure in composite materials, such as delamination and significant loss in mechanical toughness. The composite cutting series is specially designed for materials such as carbon fiber, fiberglass and G10.

Amana carbon fiber and composite steering bits

Some popular options include diamond-pattern bits cut from solid carbide and replaceable knife insert bits. These tools are designed to cut fibers cleanly, resist heat, and hold an edge longer than general cutters.

What type of bit should you use?

- Broken bits: Best for thin carbon fiber panels or where top surface finish is critical. It pushes the fibers down and reduces top edge wear.

- Broken bits: Provides better chip evacuation but may damage the top layer – great for deeper cuts or when cutting the top surface later.

- Pressure bit: Combine up and down cut flutes to provide a clean edge on both sides – perfect for cross cuts.

- Insert bits: For production shops, insert bits with replaceable carbide knives provide long life and cost effectiveness.

Spektra™ Extreme Tool Life Carbon Steel Sheet Cutting Router Bits Coated with Spiral Carbon Graphite and Carbon Fiber

Spektra™ Extreme Tool Life Carbon Steel Sheet Cutting Router Bits Coated with Spiral Carbon Graphite and Carbon Fiber

Spektra™ Extreme Tool Life Carbon Steel Sheet Cutting Router Bits Coated with Spiral Carbon Graphite and Carbon Fiber

Spektra™ Extreme Tool Life Carbon Steel Sheet Cutting Router Bits Coated with Spiral Carbon Graphite and Carbon FiberCutting tips for clean results

- Use sharp, specially designed pieces for this purpose. Even composite parts fade faster on carbon fiber – check and replace them regularly.

- High rotation speed, moderate feed rate. About 18,000-20,000 rpm with a conservative slide load is a good starting point; Adjust your device and materials.

- Take shallow passes. Multiple light passes reduce stress on the laminate and help prevent delamination.

- Employment insurance. Treadmill schedules work best; Any movement or vibration will ruin the finish.

- Avoid traditional end mills. Standard carbide bits will quickly dull, heat up and tear the fibers.

- Test on scrap first. Small test runs help dial in speed and depth before running the final section.

Example setting

machine: Medium sized CNC router with solid spindle

material: 2mm fiber board

a little: Compound cut-down router bit (e.g., Amana Tool 464110)

Spindle speed: ~19,000 rpm

Feed rate: ~1,200 mm/min

Scroll depth: ~0.5 mm

The result: smooth edges, minimal fuzz, no resin burn. After cutting, a quick hand sanding with a fine grit or diamond file produces an edge ready for bonding or clear coating.

Finishing and cleaning

After processing:

- Wipe the surface b Isopropyl alcohol To remove dust and debris.

- Lightly sand the edges if necessary, but avoid overheating the material.

- Dispose of carbon dust safely – never take it outdoors or use compressed air to clean.

conclusion

Cutting carbon fiber with a CNC can be intimidating, but with the right Amana Tool compound cutting bits, proper dust control, and tuned cutting parameters, you’ll get professional-quality results that look as good as they perform.

These bits are designed to handle the unique challenges of carbon fiber – staying sharp longer, cutting cleaner, and keeping your workshop safer.

Ready to outfit your store? Explore the full line of Amana Tool compound router bits at ToolsToday to find the right bit for your next project.