Back to school in Makerspace: Top CNC Education tools

The season to return to school is no longer just pencils and backpacks. For schools and community centers with space makers, it is also about preparing for a new year of practical learning. CNC machines have become an essential feature in many education programs, giving students experience in the real world in design, engineering, and manufacturing.

If you are a teacher, director of the program, or a student leader looking to store your MakerSpace space, the appropriate CNC tools make a big difference. Here are the best CNC Education tools that you should consider for every educational space in the productive and creative academic year.

Why CNC belongs to the semester

Adding CNC technology to the area of makers enhances practical learning of milling and steam. Students gain experience in solving problems, digital design, and manufacturing skills that are directly transferred to future jobs. Besides technical training, CNC enables creativity: students can design marks, build robot parts, craft furniture, and the initial model new ideas.

basic CNC Education tools

CNC groups start

For schools, ingenuity is the key. A good start set provides a group of bits without a large investment. Classes like Amana Tool® AMS-150 CNC Starter or Sign -004 package guarantee to cover the inscription needs, surface space, and cut – ideal for students to work with CNC.

British bits on the surface

When dozens of students share a CNC machine, the saving plate takes a beating. The fast surface is allowed to appear quickly and easy to appear so that the projects are accurately cut. It is also a great way to teach students to maintain machines and improve accuracy.

V-bits for engraving and making marks

V-Bits are the preferred classrooms. Students can design names, school slogans, or art projects, and these bits are cut clean in wood, MDF, and plastic. It is also a variety of uses for advanced signal projects with students’ progress.

Straight and pressure

The plywood and MDF are foodstuffs. The straight diving is simple and effective, while the pressure tattooing reduces tears-blessing soft and professional edges. Clean results help students maintain the motives and pride of their work.

Strong, solid carbide parts

Schools need tools that can withstand heavy use. Invested in high-quality solid carbide parts with longer tool life, safer operation, and reduced replacement costs compared to low-quality alternatives.

Material schools are usually cut

- Wood (plywood, MDF, softwood): By reasonable and tolerant prices for beginner projects.

- Plastic (acrylic, HDPE, PVC): Great signs, shows, and premium models.

- foam: Lightweight and easy to cut for architectural models or designs.

- Soft minerals (aluminum): Suitable for high school projects or the advanced university.

Choosing the right bit for each subject guarantees better results and lower frustration in the semester.

Practical advice for teachers

- Start simple: Definition of students to two -two-dimensional inscriptions or cutting before moving to complex 3D tool paths.

- Smart Budget: A small group of high-quality bits often outperforms a staircase full of cheap panels.

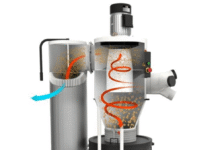

- Giving priority to safety: Dust collection, eye protection, and safe handling instructions are not negotiable.

- Maintenance education: Cleaning and storing bits properly extends their lives and shows responsibility.

The project inspiration for student makers

- Customized marks and games for cabinets or classrooms

- Parts of a robot competition or a unitary drone ingredients

- Furniture or shelves to enhance the area of the makers themselves

- Foam or acrylic models for architecture chapters and design

Bringing CNC tools leads to the separation of converting education into practical innovation. Through the right beginner groups, ski tools, and solid bits, teachers can give students the skills and confidence they need to design, build, and clarify problems creatively.

Are you ready to set your manufacturing space for success? Explore the Toolstoday Tatoday sets and ready -to -teach tools to make this academic year more innovative so far.

Note: Did you know that you can get a free CNC file bit with free United States if you are well, nevertheless? (You can also buy a CNC tool label wrapped, packed in a tube, with free shipping to the United States.)

Here at Toolstoday, we offer discount prices for educational and reform facilities that teach wooden business skills. As woodworkers ourselves, we support teachers who pass through this traditional trade for future generations.

Call our technical support and Customer Service Hotline, 888-699-3939 see if your program is eligible.

❓ Frequently Asked Questions About CNC Tools in Education

1. Why should CNC tools be integrated into classrooms?

CNC technology enhances hands-on learning by blending STEM and design. Students gain real-world skills in problem-solving, digital fabrication, and creative thinking—skills directly transferable to future careers.

2. What are the essential CNC tools for a school Makerspace?

- Starter kits like Amana Tool® AMS-150: Cover engraving, surfacing, and cutting needs.

- V-Bits: Ideal for engraving names, logos, and art projects.

- Spoilboard surfacing bits: Help maintain machine accuracy during frequent use.

- Straight and compression bits: Provide clean cuts in plywood and MDF.

- Solid carbide bits: Durable and cost-effective for heavy classroom use.

3. What materials can students work with using CNC machines?

- Wood (MDF, plywood): Affordable and beginner-friendly.

- Plastic (acrylic, HDPE, PVC): Great for signage and prototypes.

- Foam: Lightweight and easy to shape for architectural models.

- Soft metals (aluminum): Suitable for advanced high school or college projects.

4. How can teachers get started with CNC in the classroom?

- Begin with simple 2D engraving or cutting projects.

- Invest in a few high-quality bits rather than many cheap ones.

- Prioritize safety: dust collection, eye protection, and proper handling.

- Teach students how to clean and store tools to extend their lifespan.

5. Are there discounts available for educational institutions?

Yes! Toolstoday offers discounted pricing and free shipping within the U.S. for qualifying schools and training centers. Educators can contact their support hotline to check eligibility.