CNC for designers collection: foam plate, panels and pillars have become easy

Theater, films, and television requests are application sets. Lightweight, durable, and fast production. For many scenic stores, CNC routers have become an essential tool – hours of manual pieces with accurate and frequent results in the wooden panels, foam plates, and complex materials. Broadway theaters, TV studios, and production toured on CNC to present ambitious designs on narrow final dates while staying within the budget.

Why CNC is important for design group

- speed: Complex apartments, pillars, and backgrounds can be cut in minutes instead of hours.

- accuracy: Digital files ensure consistent forms, easy alternatives, and quick reviews when managers request changes.

- Diversity: From foam plate sculptures to plywood apartments, CNC can handle a wide range of scenic materials.

- Cost savings: Low work time and less wasted materials make CNC an investment that quickly pays for crowded stores.

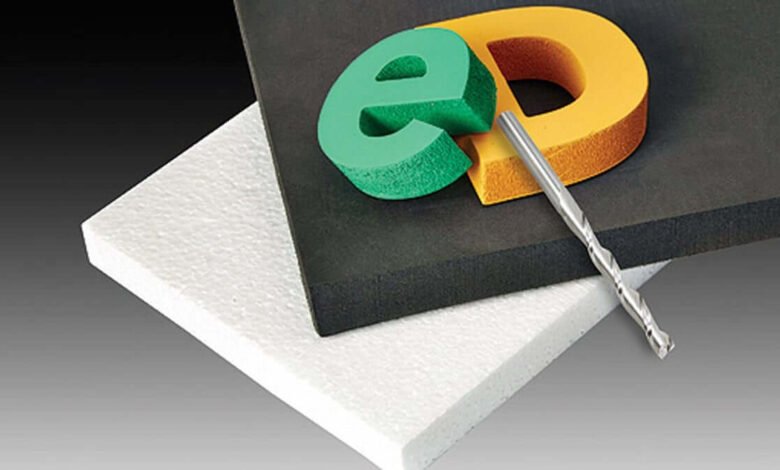

Common materials in scenic landscape construction

- Foam Panel (XPS, Eps): It is used for sculpted textures, scenic walls, and lightweight support. CNC foam tools with Titanium nitride coating (tin) allow deep cuts with smooth edges and lower corridors.

- Dark panels and MDF: The backbone of apartments and structures. The pressure Hand over the edges of the top and the bottom, clean, and reduce the finishing work before the paint.

- PVC and HDU sign board: Popular for permanent pillars and reusable banners. ZRN wrapped, preventing gossip and reducing the accumulation of heat when directing plastic materials.

- Acrylic and polycarbonate: Ideal for theater windows, light boxes, or signs. O-Flute Tools give soft edges, polished without melting.

- Aluminum and thin minerals: Used from time to time for scenic structures and pillars. Single tools orthoses covered with ZRN help reduce heat and extend the life of the tool.

Best CNC parts for designers collection

- Cut foam pieces (wrapped in tin): Designed for thick foams with precision and speed. The flushing of the smooth chip remains clean and prevents the wearing of tools.

- Compression routers: Ideal for plywood apartments and slices, leaving clear edges ready for finishing.

- Battat bits: It is necessary when you need a flawless upper surface on the panels that will be drawn or crust.

- O -flute bits: Ideal for plastic and lightweight vehicles used in the pillars and banners.

- Enter the tools: Exactly effective for high-scene stores of large size, allowing you to replace knives instead of the entire bits.

- Bit: Wonderful to carve stone, bricks, or wooden textures in foam for realistic, hypnotic finishes.

- Bit inscription: It is useful for micro character or decorative details on the allegations and banners.

- Headquarters: Decreased to cut huge foam blocks or deepest panels without compromising accuracy.

**TiAlN Coating**

Design flexibility with CNC

- Cut the sophisticated window forms and entrance directly into stunning views.

- Carrot of 3D foam, such as bricks, stone, or decorative motifs.

- Frequently duplicate panels and pillars – especially useful for wandering products that require alternatives.

- Combine materials (wood, foam, plastic) in one design for the effects of dimensions.

Tips to start

- Use the largest diameter for apartments and huge paintings to save cutting time.

- For foam, flute engineering matches to prevent rupture or melting.

- Adjust the depth of the pieces to match the thickness of the material-provides the direction that has been passing time and reduces errors.

- Consider the dust group-producing MDF and FOAM fixed dust that can interfere with finishing.

- Use a slower spindle speed with plastic and foam to prevent the edges or coarse.

- Rotation between coarse bits and finishing fetches to extend the life of the tool and improve the quality of the pieces.

Bring the scenic ideas with CNC

Whether you are building apartments on the stage for the theater or the complex pillars of the film and television industry, the correct parts of the CNC router make the scenic construction faster, safer, and more accurate. From foam tools to pressure parts, Toolstoday provides CNC professional solutions to maintain your production smoothly. And when the show should continue, reliable tools mean that you remain on time, on budget, and ready to change the next scene.