Choosing the Right CNC Router for Low Volume Manufacturing (And How to Get the Most From Your Investment)

If you’re running a small manufacturing operation, you know that every minute matters. Whether you’re crafting custom furniture, producing signage runs, or prototyping specialized components, the right CNC router can completely transform how you work. We’re talking better accuracy, higher productivity, and rock-solid consistency—all without hiring more people.

What Exactly Is “Low Volume Manufacturing”?

Let’s be clear: low-volume manufacturing isn’t a hobby operation, but it’s not a massive factory floor either. It’s that sweet spot in between where:

- You’re producing custom furniture or cabinets by the dozens, not thousands

- You run a sign shop handling regular commercial orders

- You do prototype work or contract manufacturing for specialized parts

- You need repeatable precision, but also value flexibility

For operations like these, you need a CNC router that strikes the right balance. Industrial-strength durability, yes, but in a footprint and price point that makes sense for a small to medium-sized shop. You want something tough enough for daily production runs without taking over your entire workspace.

What to Look For in a Production-Ready CNC Router

1. Table Size and Material Handling

Think about your typical projects. Larger work envelopes—say, 24″×36″ up to 48″×96″—let you nest parts more efficiently and reduce material waste. If you’re cutting full cabinet panels, oversized signs, or large components, table size directly impacts both what you can make and how many parts you can process per setup.

Pro tip: Vacuum tables or T-slot clamping systems are game-changers. They speed up part changes dramatically and improve holding accuracy, which is essential when you’re running batches.

2. Spindle Power and Duty Cycle

Here’s something many people overlook: for production work, spindle horsepower and continuous-duty rating matter more than maximum travel speed. A high-torque spindle handles dense hardwoods, plastics, and non-ferrous metals while maintaining consistent chip loads and surface finishes over long runs.

Look for machines rated for continuous use. They’ll hold tolerances longer and cut down on unexpected downtime that kills your schedule.

3. Tool Changes and Workflow Efficiency

Automatic tool changers (ATC) can save you serious time when you’re running multi-operation jobs. Even if a full ATC isn’t in the budget, features like quick-change tool holders or well-organized tool racks keep production moving and settings consistent.

4. Software Compatibility and Integration

In production work, repeatability is everything. Your router should play nicely with common CAD/CAM platforms like Vectric VCarve, Aspire, or Fusion 360. Reliable post-processing, nesting capabilities, and toolpath optimization are must-haves for efficient repeat runs.

5. Support, Training, and Parts Availability

Let’s be real: production time equals revenue. When something goes wrong, you need answers fast. Machines backed by solid technical support and readily available replacement parts—like those from Axiom, Next Wave, and STEPCRAFT (all available through ToolsToday)—keep you running when every hour counts.

Production-Ready CNC Routers Available at ToolsToday

Axiom Precision CNC Routers (Pro+, Elite, AR Series)

Axiom machines are built to work hard in small spaces. They deliver industrial-grade performance without requiring an industrial-sized footprint.

Key features:

- Heavy-duty steel frames that reduce vibration and improve cut quality

- Optional vacuum tables and fourth-axis capability for advanced workflows

- Continuous-duty spindles designed for all-day production

- Perfect pairing with Amana Tool Spektra® and carbide insert bits

Best for: Cabinet shops, furniture makers, and shops working with composites or aluminum.

Shop Axiom Precision CNC Routers →

Next Wave Shark HD Series

The Shark HD lineup is ideal for small production runs, signage work, and woodworking businesses that need consistent accuracy without taking up tons of floor space.

Key features:

- Rigid aluminum bridge with precision linear bearings

- Plug-and-play control system that simplifies training for small teams

- Excellent choice for sign replication and engraving workflows

Best for: Sign makers, custom engravers, and short-run woodworking production.

STEPCRAFT D Series (D.840 / D.600)

STEPCRAFT brings modular German engineering to small-scale production and prototyping in wood, plastics, and light metals.

Key features:

- Modular design supports easy tool head swaps

- Solid balance of precision, footprint, and affordability

- Excellent for R&D labs and specialty parts manufacturing

Best for: Prototyping shops, specialty component manufacturing, and lean production facilities.

CMaster PT-408 Panther ATC

CMaster positions their PT-408 Panther ATC as the ultimate platform for small shops that need to cut full 4’×8′ sheets. (It’s also available in 4’×4′ and 5’×10′ configurations.) They might be right—just make sure you can actually get it through your door!

Tools and Accessories That Maximize Your ROI

A CNC router is only as good as the tooling and setup you pair with it. To maximize uptime and minimize cost per part, focus on these essentials:

Router Bits: Invest in quality bits like Amana Tool Spektra® coated or carbide-tipped options. They deliver cleaner cuts and longer tool life during production runs.

Work Holding Systems: Vacuum tables, T-slot clamps, and spoilboards keep parts secure and ensure repeatability between runs.

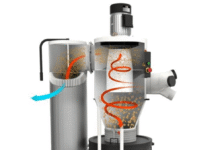

Dust Collection: Effective dust extraction improves surface quality, extends tool life, and keeps your shop safer for operators. See dust collection solutions →

Maintenance: Regular lubrication and inspection schedules protect spindle bearings and linear motion components—small effort, big payoff.

Getting the Most From Your CNC Investment

For small manufacturers, success boils down to three things: precision, uptime, and workflow efficiency. The right CNC router doesn’t just cut material—it reduces waste, cuts setup time, and minimizes operator fatigue.

Here’s your action plan:

- Match table size to your production mix – Don’t overbuy or limit yourself

- Choose spindle power and duty cycle for your toughest materials – Build headroom into your capability

- Invest in accessories that drive repeatability – These pay for themselves quickly

- Partner with suppliers who offer real support – Downtime is too expensive to risk

Frequently Asked Questions

What’s the difference between a hobby CNC router and a production-grade machine?

Production machines are built for continuous duty cycles with heavier frames, more powerful spindles, and components rated for daily use. Hobby machines are typically lighter duty with lower-powered spindles and aren’t designed to run 8+ hours per day. Production routers also generally offer better support, readily available parts, and compatibility with industrial tooling.

How much should I budget for a low-volume production CNC router?

Entry-level production machines typically start around $5,000-$10,000, while more capable systems with larger work envelopes and automatic tool changers range from $15,000-$50,000+. Remember to budget an additional 20-30% for tooling, work holding, dust collection, and initial training.

Can I cut metal on a CNC router designed for wood?

Many production CNC routers can handle non-ferrous metals like aluminum, brass, and copper with the right spindle, speeds, and tooling. However, cutting requires proper speeds and feeds, adequate cooling/lubrication, and carbide or coated tooling. Always check your machine’s specifications and consult with the manufacturer before attempting metal cutting.

What maintenance does a CNC router require?

Regular maintenance includes daily cleaning and debris removal, weekly lubrication of linear rails and ball screws, monthly inspection of belts and couplings, and periodic calibration checks. Budget 30-60 minutes per week for routine maintenance. Proper maintenance dramatically extends machine life and maintains accuracy.

How long does it take to learn CNC router operation?

Basic operation can be learned in a few days, but becoming proficient typically takes 2-3 months of regular use. CAD/CAM software has a steeper learning curve—budget 1-3 months to become comfortable with design and toolpath generation. Many manufacturers offer training programs, and platforms like Vectric have excellent tutorial libraries.

Should I buy new or used for my first production CNC router?

For production work, buying new is generally recommended. You get full warranty coverage, manufacturer support, and known machine history. Used machines can have hidden wear, outdated control systems, or unavailable replacement parts. If you do buy used, have an experienced technician inspect it first and verify parts availability.

What file formats do CNC routers typically work with?

Most CNC routers accept G-code files generated by CAM software. Your CAM software (like VCarve, Aspire, or Fusion 360) typically imports common design formats like DXF, DWG, SVG, AI, PDF, and various 3D formats (STL, STEP, OBJ). The key is ensuring your post-processor is configured correctly for your specific machine.

Ready to Upgrade Your Production Capabilities?

Explore our complete selection of production-ready CNC routers and Amana Tool cutting tools designed for professional continuous use.

Helpful Resources

- ToolsToday CNC Router Buying Guide

- Amana Tool Complete Catalog

- CNC Dust Collection Solutions

- Vectric Software Tutorials

- Fusion 360 Manufacturing Resources

- CNC Cookbook: Feeds and Speeds Guide