Architectural Millwork: Profiles, Materials, and Modern Tooling

The detailed wooden trims, moldings, and components that define interior spaces have always been about accuracy and elegance. From the classic **crown molding** to contemporary casing, professional **millworkers** are tasked with delivering beautiful and consistent profiles. Today’s shops face a dual challenge: honoring traditional designs while working efficiently with modern materials and tools.

For context, **wainscoting** is the paneling on the lower part of the wall. The **chair rail** is the horizontal trim section above the wainscoting, and the **baseboard** is below.

The Essential Profiles Every Millworker Should Know

While design trends evolve, certain features remain essential to architectural millwork. These shapes form the foundation of most trim packages and restoration projects:

- Crown Molding: The trim that transitions the wall to the ceiling. Variations include Cove, Ogee Crown, and D-Cove profiles.

- Baseboard (Skirting Board): Protects the bottom of the walls. It’s usually simple but sometimes detailed with beads or coves.

- Casing / Architrave: The trim that frames doors and windows. Designs range from a simple round-over to complex, multi-step patterns.

- Chair Rail and Picture Rail: Originally functional, now primarily decorative.

- Panel Molds / Wainscoting: Used to define wall panels or frame the lower section of a wall.

- Specialty Details: Small accents like Beads, Coves, Ovolos, Roman Ogees, Fillets, and Lamb’s Tongues add fine detail.

For restoration work, the ability to **precisely match an existing profile** is often the make-or-break factor for a project.

Modern Solutions for Creating Millwork Profiles

Traditional shapers and manual routers still have their place, but today’s millworkers increasingly rely on **CNC machinery** and **insert tooling** for accuracy, repeatability, and efficiency. Here is how various tools fit into the modern workflow:

Router Bits

A handheld or table-mounted router with a single-profile bit is one of the most straightforward ways to cut architectural details. Edge-forming profiles like *Ogee, Cove, Roundover,* and *Bevel* are ideal for smaller jobs, in-shop cutting, or custom accents.

Profile Bits on CNC Routers

Yes, CNC machines *can* run a profile router bit. This is useful when you need an Ogee or Cove to repeat on flat panels. However, most shops prefer other tooling for more sophisticated templates, as CNC flexibility comes from programming the tool path rather than a fixed cutter shape.

Standard CNC Tooling

The spiral, straight, and compression bits are the real workhorses of the CNC router. Through programmed tool paths, operators can “build” almost any dedicated molding profile. This is the way to go for wide crown moldings or unique historical reproductions.

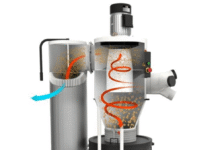

Insert Profile Tooling

For high-volume runs, **Insert Profile Cutters** are right. The replaceable knives keep long-term costs down and maintain consistent performance, especially when working with abrasive sheet goods like MDF. These can be used on CNCs or shapers, depending on the shop’s setup.

*Professional millworkers prefer solid carbide insert bits like the **CNC TRU-Point** bits (above) or interchangeable steel profile cutters (below), for long edge life and cost savings.*

*The **Profile Pro™** system features over 135 different interchangeable steel knife patterns, ranging from carpentry molding to door profiles, all usable with one cutter head. Blank (un-ground) knives are also available for custom patterns.*

Shaper Cutters

Shapers are indispensable for high-volume production of security profiles. Many shops still rely on their ability to handle wide cuts and long production runs—especially when historical details are being widely reproduced.

Which do professionals use more—Shapers or CNCs?

Most millwork shops still rely heavily on **shapers** to run their daily moldings. The shaper easily handles wide stock, long lengths, and repeatable custom profiles.

At the same time, CNC adoption has grown quickly, especially in shops that also build cabinets, wall panels, or custom architectural elements.

Many professional shops now operate a hybrid setup: they use shapers for high-volume, standard profiles and CNCs for specialized jobs where flexibility is crucial. The best solution often depends on your shop’s volume, space, and the variety of profiles you need to produce.

*Molding work ranges from a simple Ogee shape made with a handheld router and bit (above, Amana Tool 54297 Carbide-Tipped Baseboard Ogee Edge) to complex profiles created on a shaper (below, Amana SC668 Carbide-Tipped 3-Wing Base). Whatever your preference or tool, Amana has you covered.*

Material Considerations

Millwork is not only about the profile—it’s also about the material:

- Solid Wood

For a rich, stained look, natural **hardwoods** such as Oak and Mahogany stain beautifully. The color of the stained solid wood crown will add character and warmth to any room, and because the material is dimensionally stable, solid wood allows us to create any pattern we love. ***Pro Tip:*** Use exceptionally sharp tools to avoid burn marks or tear-out. - Softwood

Softwood crown moldings, such as **Pine** or **Poplar**, are often more affordable than high-grade solid wood. It is easier to cut and sand than hardwood, and it is an excellent choice for profiles that will be painted. ***Pro Tip:*** Softwood is easily cut but can compress under dull tools. They also have more resin than solid wood, which will gum up your blades faster. - MDF

**MDF** crown (a wood-based material using wood fibers with industrial resin) is an inexpensive alternative for painted pieces. MDF will not split when cut, is easy to cut with a miter saw, and resists warping. ***Professional Advice:*** MDF is highly abrasive. It requires durable carbide or insert tooling due to its density. - Polyurethane

This crown molding is weather-resistant, scratch-resistant, and corrosion-resistant, making it one of the most durable types. However, it is generally manufactured in white and will not take stains well for a natural finish. - Flexible

When you encounter a radius entryway or curved window, standard options won’t work. **Flexible molding** is made from a polymer resin designed to curve and bend around shapes, making it easy to trim curved openings without breaking or splitting. - Aluminum, Copper, and Steel

Often used in modern design, metal crown trim is characterized by a hard-service construction available for use as a decorative accent. It is formed into inside and outside corners, eliminating miter pieces, which simplifies installation.

The feed rate, tooling material, and chip evacuation all play a major role in producing clean results, regardless of the material.

Pro Tips for Millworkers

- **Identify Profiles:** Match existing profiles for restorations by creating molds or scanning with a CNC.

- **Jigs and Fences:** Use **jigs and fences** to maintain consistency across multiple pieces.

- **Tooling Volume:** Choose tools by operating volume—stock router bits for short runs, insert tooling for production.

- **Safety:** Mind safety when using large profile cutters; always use the correct guards and feed speeds.

Toolstoday Solutions

At Toolstoday, we stock a wide range of **Amana Tool** architectural router bits, along with **CNC tooling** and **shaper cutters** for every type of millwork application. For production environments, we feature **Insert Profile Tooling** that offers long-term performance and easy knife replacement.

Conclusion

Architectural Millwork continues to combine tradition and innovation. By understanding classic profiles and choosing the appropriate modern tools—whether it’s the router, shaper, CNC, or specialized insert cutter—professional millworkers can achieve timeless results with today’s efficiency. The correct tools don’t just cut the wood; they help in shaping the space.

Frequently Asked Questions (FAQ)

Q: What is the difference between molding, trim, and millwork?

A: **Millwork** is the broad term for all custom-fabricated wood products in a building (doors, cabinets, trim). **Molding** and **Trim** generally refer to the finished linear pieces of millwork (like crown, baseboard, and casing) that cover joints and add decorative detail.

Q: What is the best material for staining vs. painting?

A: **Staining:** Hardwoods like Oak, Maple, and Mahogany offer the best grain and depth. **Painting:** Softwoods (Pine, Poplar) and MDF are the most common and cost-effective choices for a painted finish.

Q: Can I use a profile router bit on a CNC router?

A: Yes, you can. However, for complex shapes, a CNC is often more efficient using standard straight or spiral end mills to “build” a profile using a series of programmed passes.

🛠️ Technical and Tooling Resources

- Architectural Millwork: Classic Profiles, Modern Solutions – ToolsToday

This article closely mirrors your content, offering detailed explanations of crown molding, baseboards, and casing profiles, along with modern CNC and insert tooling techniques 1. - Amana Tool Profile Library

A visual catalog of router and shaper bits, ideal for readers wanting to explore specific profile shapes and tooling options.

📘 Industry Standards and Catalogs

- Architectural Woodwork Institute (AWI)

The go-to authority for millwork quality standards, specifications, and best practices. Great for readers seeking professional benchmarks. - ITC Millwork Product Catalog

Offers hundreds of stock profiles and real-world applications, useful for readers looking to compare or source molding types 2. - Trademark Architectural Millwork Catalog (PDF)

A downloadable catalog with over 400 profiles—perfect for restoration specialists or designers seeking inspiration 3.

🌲 Material Science and Wood Properties

- The Wood Handbook – USDA Forest Products Laboratory

A comprehensive guide to wood species, properties, and usage—ideal for readers curious about material behavior, especially when choosing between hardwood, softwood, MDF, or polyurethane.

Resource Links

- Architectural Woodwork Institute (AWI): Industry standards for quality and performance.

- Amana Tool Profile Library: A visual resource for understanding various router and shaper profile shapes.

- The Wood Handbook: A comprehensive guide to wood properties and uses from the USDA.