ROI on CNC router parts: Calculate tool life and cost per part

How to measure true ROI on your CNC router parts by understanding tool life, cost per part, and what really drives your ROI.

Why tool ROI matters more than ever

In today’s CNC shops, margins often come down to the smallest numbers — seconds shaved off cycle time, fractions of a millimeter in tool wear, or a few dollars saved per job. One of the most overlooked cost factors in any production setting is the life of the cutting tool itself.

A steering unit doesn’t just cost what’s printed on the label. Each tool accounts for setup time, machinery wear and quality of the final product. The smartest manufacturers and shop owners are counting Cost per partAnd not just cost per bit, this is where your tooling choices start to make a tangible difference.

Understand the tool life and cost per part

Start simple. for you Cost per part The router bit is:

Tool cost ÷ number of parts produced = cost per part

If a $40 piece cuts 100 parts before it becomes dull, each part actually costs $0.40 in tooling. If another $60 is enough for 250 parts, that’s only $0.24 per part — a Save 40% In operating cost. Now multiply that across thousands of parts per month or multiple CNC stations, and a “premium” part becomes a financial benefit, not an expense.

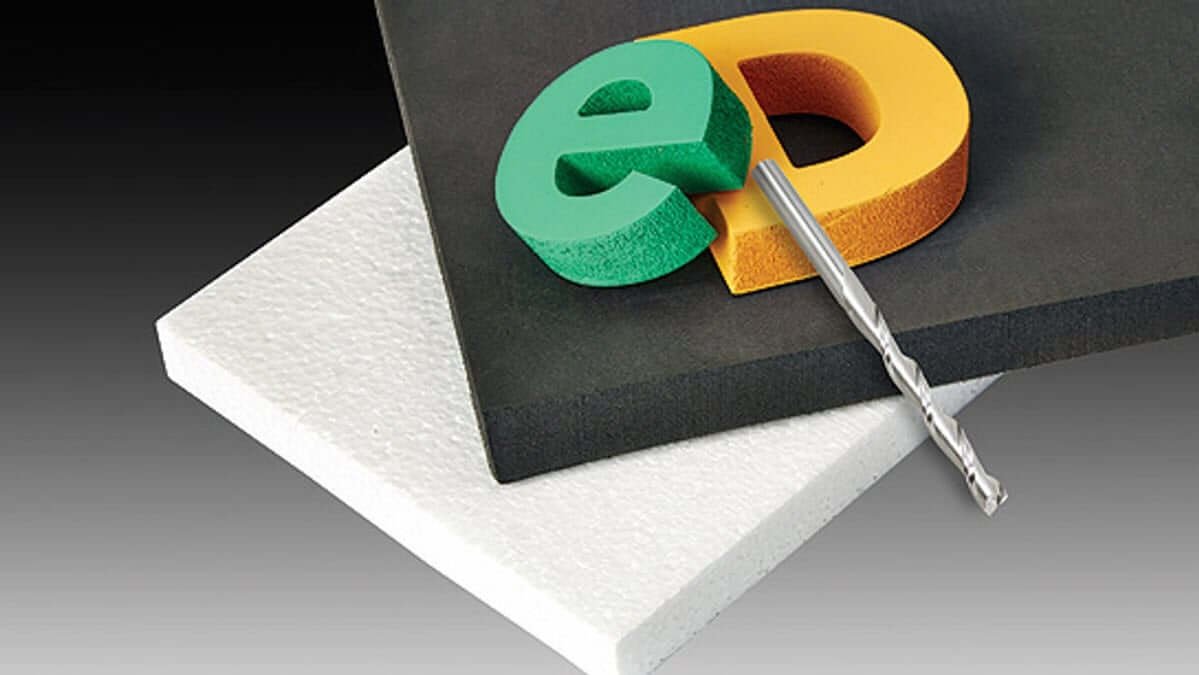

Spectra’s unique carbide grade, increased clearance geometry, and sharp cutting edges with polished flutes provide a superior finish and longer tool life especially in abrasive materials. Great for production settings. Primarily used on CNC machines but can be used with portable and table-mounted routers.

Spectra’s unique carbide grade, increased clearance geometry, and sharp cutting edges with polished flutes provide a superior finish and longer tool life especially in abrasive materials. Great for production settings. Primarily used on CNC machines but can be used with portable and table-mounted routers.Where the numbers change: paint, geometry and materials

The life of a tool is shaped by three main factors: Cutting materials, engineeringand paint. Each one affects how long a part lasts, how cleanly it is cut, and ultimately, the cost of producing each part. Understanding how these factors interact helps explain why two similar pieces can deliver very different returns on investment.

Cutting materials

The basis of any router bit is the material it is made of. Solid carbide Parts—like those in the Spektra™ line—provide the best combination of hardness, rigidity, and heat resistance for CNC work. Unlike carbide-tipped bits, which attach small carbide inserts to a steel body, solid carbide bits maintain consistent force throughout the tool. This translates to smoother cuts, less vibration, and better edge retention under sustained loads. When accuracy and repeatability are important, the bit core material is the first place the return on investment begins.

Engineering

While paint often highlights, engineering It plays an equally important role in tool life and finish quality. Geometry refers to the exact shape of the bit and its angles—comb, relief, and helix angles; Number and polish of flutes. And even the transition between the cutting edge and the shank.

Amana’s Spektra™ pieces are known for their properties Precision side geometry and polished flutesWhich reduces friction and heat buildup. Sharper, more precise shears cut material cleanly rather than scraping it, extending tool life and producing smoother surfaces. Each bit type uses geometry tuned to its task: Compression bits Balancing up and down cut spirals to reduce tearing, Flute bits Use a deep, polished flute to efficiently remove plastic chips Spiral bits Combines cutting and drilling for cleaner cuts in wood and composite materials. The coating protects that geometry, but it’s the geometry itself that determines how efficiently it cuts, removes chips, and resists corrosion over time.

paint

The standout performer in the Amana lineup is Spektra™ Extreme Life Coating, which uses… nACo® nanocomposite layer To improve corrosion resistance, heat resistance, and surface smoothness. The paint measures approx 4500 Vickers hardness On the cutting surface – support A Conservative, public-facing claim of up to 2.5x longer tool life Compared to uncoated bits.

It’s physics on the edge: Harder coatings resist fine chipping, while lower friction helps evacuate chips more efficiently and reduces heat – two of the biggest enemies of tool life. The result is a sharper edge that lasts longer, cuts cleaner, and runs cooler, improving the cost of each part across nearly every category of CNC material.

Spektra compression bits are designed for CNC applications that require high feed rates and flawless compression cuts. Particularly suitable for double-sided melamine or laminated materials.

Spektra compression bits are designed for CNC applications that require high feed rates and flawless compression cuts. Particularly suitable for double-sided melamine or laminated materials.Case example: Cost per part in real CNC production

Think of your favorite paper goods store: Secretariat 46170-K 1/4" Router compression bit.

| Bit type | price | Average life (parts) | Cost per part |

|---|---|---|---|

| Uncoated compression bit | $40 | 100 | $0.40 |

| Spectra™ 46170-K | $60 | 250 | $0.24 |

Even with a conservative 2.5x multiplier, a coated bit produces more parts per tool, fewer bit changes, and less downtime — approx. Save 40% per part Before you even count the cleaner edges and reduced rework.

The same story is repeated across popular models:

- 46202-K(1/4") Spiral cutting

- 46225-K (1/8") Spiral cutting

- 46170-K(1/4") pressure

- 46172-K (3/8") pressure

- 51411-K (1/8") Single flute for spiral plastic cutting “O”.

- 51404-K (1/4") Single flute for spiral plastic cutting “O”.

advice: When cutting materials that generate heat or fine dust – acrylic, HDU, plywood strips – the difference in edge wear between coated and uncoated pieces becomes significant after just a few runs.

These “O” spiral steel plastic cutting bits use the finest fine grain carbide, have a special edge processing system, and feature a highly polished cutting edge with a unique “mirror finish”, resulting in clean cuts, superior finish and longer tool life. The spiral flute sharpening/finishing process increases feed rates, allowing more linear feet to be driven in less time.

These “O” spiral steel plastic cutting bits use the finest fine grain carbide, have a special edge processing system, and feature a highly polished cutting edge with a unique “mirror finish”, resulting in clean cuts, superior finish and longer tool life. The spiral flute sharpening/finishing process increases feed rates, allowing more linear feet to be driven in less time.Return on investment after longevity: hidden complications

- Reduce downtime: Fewer tool changes mean less time re-zeroing, checking offsets and restarting production.

- Faster feed and speeds: Lower friction and cleaner chip evacuation often support modest increases in speed without risking tool burn.

- Low scrap rate: Sharp, hard edges reduce tearing, chatter and melting, resulting in cleaner parts and less rejection.

- Machine longevity: Smooth cutting reduces load and vibration on the spindle, supporting longer machine life.

Practical ROI for small CNC shops

You don’t need a full analytics package. Follow some basics:

- How many sheets or parts does the piece produce before retirement?

- Approximate operating hours for each tool?

- Time lost for each tool change (setup, check, check)?

Switching from uncoated screws to Spektra-coated pieces can significantly reduce tool changes – often saving an additional hour or two of productive machining per week. This is a tangible return on investment.

Measure what matters

Keep a log or simple spreadsheet of bit changes, materials and hours worked. Patterns quickly emerge, and justifying the cost of sophisticated tools becomes self-evident.

If your team regularly cuts dense composite materials, MDF panels, or plastic materials, CNC bits coated with Spectra Deliver clear gains:

- Longer tool life (general safety claim: up to 2.5×)

- Cleaner edges and finishes

- Fewer interruptions and changes

- Lower real cost per part

Explore Spektra™ coated CNC router bits

Find a match for your material and application: the Spektra™ collection at ToolsToday.