Choosing the Right CNC Router for Low Volume Manufacturing (And How to Get…

For small manufacturers, every minute and every part counts. Whether you produce custom furniture, short-run signage, or prototyping components, the right CNC router will transform your workflow—enhancing accuracy, productivity, and consistency without adding headcount.

What does “low volume manufacturing” really mean?

Low-volume manufacturing isn’t hobby-level tinkering—but it’s not a full-scale factory, either. It’s that productive middle ground:

- Custom furniture and cabinets run by the dozens, not thousands

- Register shops that produce fixed commercial orders

- Prototype or contract manufacturing of specialized parts

- Companies that rely on repeatable accuracy, but value flexibility

For these operations, the ideal CNC router is balanced Industrial durability with a manageable footprint and cost — Durable enough for daily production, and convenient size for a small or medium sized shop.

Key factors when choosing a production-grade CNC router

1) Table size and material handling

Larger working space (for example, 24"×36"48"×96") Increases the efficiency of paper goods and interlocking parts. If you’re cutting cabinet panels, full-size signs, or large components, not only does the size of the table determine what works for you, but also the number of parts you’re processing for each setup.

2) Spindle power and duty cycle

For production work, spindle horsepower and continuous service rating are more important than maximum travel speed. High torque spindles handle dense hardwoods, plastics and non-ferrous metals while maintaining consistent chip load and surface finish over the long term.

Look for routers designed for continuous use – They will maintain tolerances longer and reduce unplanned downtime.

3) Tool change and workflow efficiency

Automatic tool changers (ATC) save significant time when running multiple operations. Even without full ATC, hot-swap collars or organized tool racks can keep productivity steady and settings consistent.

4) Software compatibility and integration

Repetition is everything. Choose a router that works well with common CAD/CAM platforms (e.g. Victric VCarve, Aspire, Fusion 360) and supports reliable postprocessing, nesting, and tasks typical of repetitive runs.

5) Support, training and availability of spare parts

Production time is revenue. Machines backed by reliable support and availability of replacement parts – like those from Axiom, Next Wave, and STEPCRAFT (offered by ToolsToday) – keep your shop running when every hour counts.

CNC routers for low volume production are available on ToolsToday

Axiom Precision CNC Routers (Pro+, Elite, AR Series)

Designed to work hard in small spaces, Axiom Res The machines deliver industrial-grade performance without leaving an industrial footprint.

- Solid steel frames reduce vibration and improve cut quality

- Optional vacuum table and fourth axis for advanced workflow

- Continuous service spindles designed for sustainable production

- Pairs excellent with Amana Tool Spektra® and carbide insert bits

Best for: Cabinet shops, furniture makers and light composite or aluminum production.

Shop precision CNC routers from Axiom ›

The next Wave Shark HD series

the Shark HD The set is ideal for small production runs, signage, and woodworking companies that need consistent accuracy in a small space.

- Solid aluminum bridge with precision linear bearings

- The plug-and-play console simplifies training for small teams

- A great choice for signage duplication and engraving workflows

Best for: Sign makers, custom engravers and short run woodworking production.

Shop CNC routers for the next wave ›

Stepcraft D Series (D.840 / D.600)

Stepcraft Brings modular German engineering to small scale production and prototyping in wood, plastic and light metal.

- Modular design supports easy tool head swaps

- A solid balance of precision, footprint and affordability

- Excellent for laboratories and specialty parts manufacturing

Best for: Prototyping, specialty components, and lean manufacturing laboratories.

SHOP CNC STEPCRAFT SYSTEMS ›

Tools and accessories that double your return on investment

A CNC router is only as good as its tools and settings. To maximize uptime and minimize cost per part, focus on:

- Router bits: Choose Amana Tool Spektra® coated or carbide-tipped bits for great cuts and long tool life during production operations.

- Suspension systems:Vacuum tables, T-slot clamps, and spoiler plates keep parts safe and repeatable.

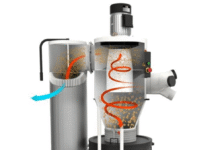

- Dust collection: Efficient extraction improves surface quality and operator safety. See dust collection solutions.

- maintenance: Lubrication and inspection schedules protect shaft bearings and linear motion components.

Get the most out of your CNC investment

For small manufacturers, success comes down to Accuracy, uptime and workflow efficiency. Not only does a proper CNC router cut material, it reduces waste, setup time, and operator fatigue.

- Match the table size to your production mix

- Choose the spindle power and duty cycle for your hardest materials

- Adopt accessories that drive redundancy

- Count on support that reduces downtime

Are you ready to upgrade?

Explore our full range of production-ready CNC routers and Amana tool parts designed for continued professional use.