What Is Wood Veneer? How Wood Veneer Wall Panels Transform Interiors

Imagine walking into a room and instantly sensing warmth, texture, and timeless style — all without the cost, waste, or complexity of solid wood installations. That’s the promise of wood veneer.

Wood veneer is a thin slice of real wood that’s bonded to a stable backing. It captures the grain, color, and character of solid wood while using far less material — making it a smart, beautiful choice for designers and homeowners who want authentic wood looks with a lighter environmental footprint.

At Woody Walls, our wood veneer wall panels combine real-wood aesthetics with low-VOC finishes and non-toxic adhesives, handcrafted for easy installation and long-lasting results. They’re ideal for accent walls, offices, media backs, and anywhere you want the natural beauty of wood without heavy renovation.

What Is Wood Veneer and How Is It Made?

Wood veneer is produced by slicing thin sheets from carefully selected logs. Those slices — often less than 1–3 mm thick — reveal the natural grain and figure of the tree. The thin sheets are then dried, graded, and bonded to a stable substrate (like plywood, MDF, or an engineered backing) using durable, low-VOC adhesives.

Common face species include oak, walnut, maple, and ash — chosen for their attractive grain and stability. Because veneer uses thin slices, it delivers the appearance of solid wood while conserving valuable timber and lowering costs and weight.

Typical steps in veneer production

- Select and prepare logs (often steamed or conditioned).

- Saw or peel logs into thin sheets (slicing, rotary peeling, or sawing).

- Dry and grade the veneer sheets.

- Bond veneers to a substrate using non-toxic, low-VOC adhesives.

- Finish with stains, oil, or clear low-VOC coatings.

Our process emphasizes safety and sustainability: VOC-free finishes, responsible sourcing, and non-toxic adhesives ensure panels are safe for your home and kind to the environment.

Why Choose Wood Veneer Wall Panels for Interiors?

Wood veneer wall panels deliver an authentic wood look with advantages that suit modern living:

Luxury meets practicality

Veneer provides the richness and grain of real wood but in a lighter, more manageable panel. It’s easier to handle and often more dimensionally stable than full solid wood, so installations are simpler and less costly.

True warmth and character

Each veneer panel retains natural variation in grain and tone, giving your room a unique, warm, and inviting atmosphere.

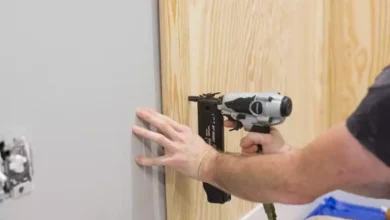

Easy DIY-friendly installation

Many veneer wall panels are designed for simple installation with minimal tools. They’re ideal for:

- Accent walls in living rooms and bedrooms

- Office backdrops and media walls

- Retail fit-outs and hospitality spaces

Versatile finishes

Veneer panels can be finished to match any decor — from natural oil finishes that emphasize grain to stained or lacquered surfaces for a modern look.

Sustainable choice

Because veneer uses less solid wood per square foot, it’s an inherently more resource-efficient option. Combine that with responsibly sourced timber and low-VOC finishes, and you have a greener alternative to solid-wood cladding.

How Wood Veneer Panels Transform a Room

Add natural warmth and texture

Veneer panels bring the tactile beauty of real wood into interiors — the natural grains and tones add depth and visual interest that make rooms feel welcoming and timeless.

Lighting and veneer

Combine veneer panels with recessed LED channels or indirect lighting to highlight grain and create a layered ambiance. A well-lit veneer wall can become a dramatic focal point.

Practical advantages

Because veneer panels are lighter and engineered, they’re easier to transport and install. They also usually require less substructure work than solid wood coverings.

Choosing and Installing Veneer Panels

What to look for when buying

- Species and grain pattern (oak, walnut, maple, etc.).

- Substrate type (MDF, plywood, or engineered backing).

- Finish and VOC certification.

- Panel dimensions and installation method (tongue-and-groove, peel-and-stick, glued).

Basic installation tips

- Prepare walls: clean, dry, and level the substrate.

- Acclimate panels to room conditions before installation.

- Use recommended adhesive or mechanical fixing as specified by the manufacturer.

- Seal cut ends and joints with appropriate trim or caulk for a finished look.

If you plan a DIY install, consider requesting samples first to verify color and grain under your room’s lighting.

Frequently Asked Questions

What is wood veneer?

Wood veneer is a thin layer of real wood sliced from logs and bonded to a stable substrate. It delivers the look of solid wood while using less material.

Are veneer panels durable?

Yes — when produced and finished properly, veneer panels are durable, stable, and suitable for interior cladding. The substrate and finish influence long-term performance.

Can veneer be used in bathrooms or kitchens?

Veneer can be used in kitchens and bathrooms if you choose waterproof backings, appropriate finishes, and sealed trim. Avoid direct water exposure unless specifically rated for wet areas.

How is veneer different from laminate or engineered wood?

Veneer uses a real wood face. Laminate typically uses printed images under clear wear layers to mimic wood. Engineered wood (like engineered hardwood flooring) combines layers of wood veneers or plies for stability.

Do veneer panels require special maintenance?

No special care is required beyond regular dusting and occasional cleaning with manufacturer-recommended products. Avoid harsh chemicals or excessive moisture.

Recommended resources

- Woody Walls – Wood veneer wall panels & collections

- Houzz – Wood veneer inspiration and projects

- Home Depot – Trim, finishes, and installation supplies

- Woodworking Network – Industry articles on veneer production and finishes