Why CNC Techniques Furniture is the Future of Woodworking: 7 Facts

Imagine making custom furniture with ease and precision. This is now possible with CNC woodworking. It’s changing the game in the woodworking world. We’ll see how CNC woodworking is making furniture creation better and more precise.

Introduction to CNC Woodworking

CNC woodworking is set to change woodworking forever. It makes complex designs and cuts with ease. This means we can make custom and modern furniture like never before.

Key Takeaways

- CNC woodworking offers precision and efficiency in furniture creation

- Custom furniture can be created with ease using CNC techniques

- Modern furniture design is being transformed by CNC woodworking

- CNC woodworking is a game-changer for the furniture industry

- CNC techniques furniture is the future of woodworking

- CNC woodworking allows for complex designs and precise cuts

- CNC techniques are ideal for creating custom and modern furniture

Understanding CNC Techniques Furniture: A Modern Revolution

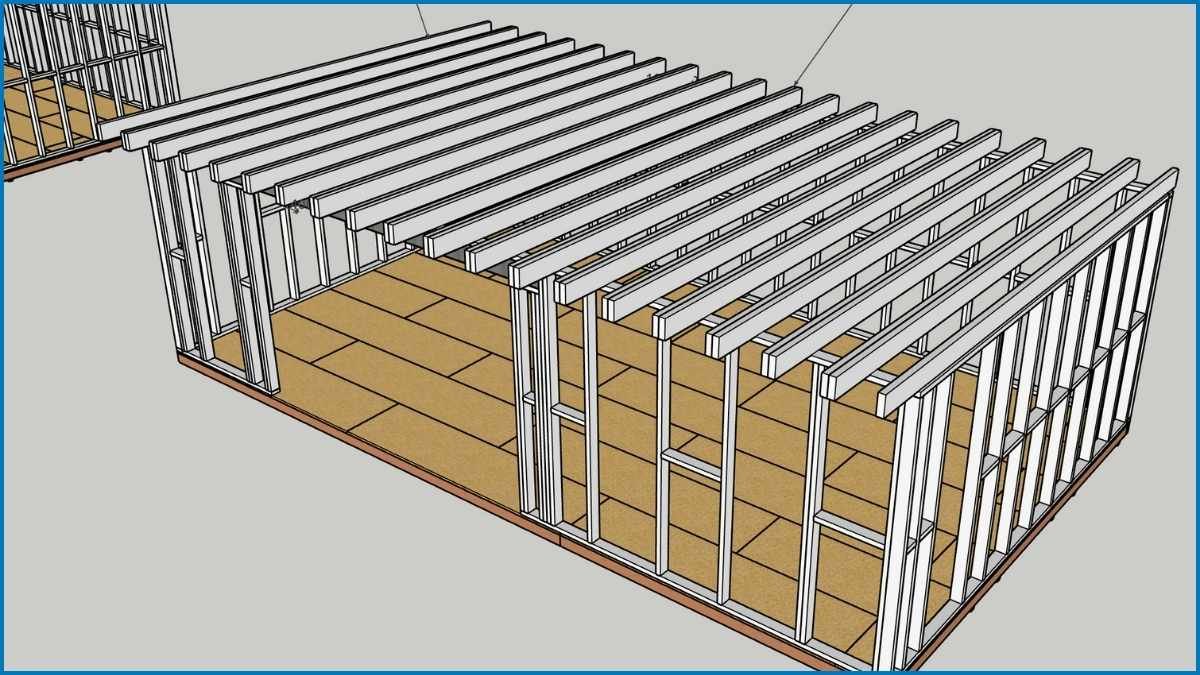

CNC techniques furniture has changed the woodworking world. It allows for precise cuts, making complex designs possible. This new way of making furniture is more accurate and uses less wood.

The shift from old to new woodworking is big. CNC machines help make high-quality furniture fast. They meet the need for unique and detailed designs.

Key Components of CNC Furniture Production

Some important parts of making CNC furniture include:

- Precision cutting tools

- Advanced software for design and programming

- High-quality materials and finishes

These parts help make furniture that stands out. CNC machines can make complex shapes and custom designs. This opens up new possibilities in furniture design.

The need for special and detailed furniture keeps growing. CNC techniques will play a bigger role in the future. This will lead to more innovation in the industry.

The Precision Advantage of Computer-Controlled Woodworking

Computer-controlled woodworking is way more precise than traditional woodworking. CNC router techniques let wood be cut and shaped with amazing accuracy. This results in designs that are perfect.

This precision is great for diy furniture projects. These projects often need intricate cuts and complex shapes.

Using CNC router techniques in diy furniture projects is very precise. It’s hard to get this level of precision by hand. This makes it perfect for creating unique and customized furniture.

- Increased accuracy and precision

- Improved consistency and quality

- Reduced waste and material costs

- Enhanced design capabilities

By using computer-controlled woodworking, you can make stunning furniture. It shows off your creativity and skill. CNC router techniques are great for both new and experienced woodworkers.

Essential CNC Router Techniques for Furniture Making

CNC router techniques are key in furniture making. They help cut, carve, and assemble wood. Woodworkers can learn these skills from cnc techniques furniture pdf guides.

In furniture making, cnc techniques boost productivity and efficiency. Woodworkers can find lots of info on cnc router techniques. This includes basic cutting and carving methods.

Basic Cutting and Carving Methods

These methods include:

- Profiling: cutting intricate shapes and designs

- Routing: creating decorative edges and patterns

- Drilling: making precise holes for joinery and hardware

Advanced Joinery Techniques

Advanced joinery like mortise and tenon, and dovetail joints, can be done with cnc router techniques. This makes wood pieces strong and durable.

Cost Analysis: CNC vs Traditional Furniture Manufacturing

Cost is key in furniture making. A cnc machine costs a lot at first. But, it saves money in the long run.

A cnc machine makes complex designs, like a cnc couch, faster and more accurately than old methods.

Cnc machine production is more efficient. It cuts down on waste and labor needs. This means lower costs and quicker production.

Also, cnc couch designs are easy to make in big numbers. This is great for making lots of furniture.

Here are some big pluses of using a cnc machine for making furniture:

- Increased precision and accuracy

- Faster production times

- Reduced material waste

- Lower labor costs

Even though a cnc machine costs more at first, it’s worth it. It lets makers create unique, high-quality items like a custom cnc couch.

Innovative Design Possibilities with CNC Furniture Production

CNC furniture production has changed woodworking. It lets designers and makers create complex designs. Many cnc furniture design files free download options are out there to start projects.

One big plus of CNC furniture making is saving materials and cutting down on waste. Designers use special software and machines to make detailed designs. This saves money and helps the environment. For more on cnc furniture plans and saving materials, check out online guides.

- Creating complex geometric patterns and shapes

- Integrating custom designs and logos

- Optimizing materials and reducing waste

CNC furniture making is getting more popular. It lets designers and makers make unique, high-quality items. With the right tools, the designs can be endless. And with cnc furniture design files free to download, it’s easier than ever.

Sustainable Practices in CNC Techniques Furniture

CNC plywood furniture is getting more popular because it’s good for the planet. CNC machines can make things with less waste and lower carbon emissions. This makes CNC plywood furniture a greener choice.

Some ways CNC woodworking is green include:

- Using materials from nearby to cut down on emissions from transport

- Improving how things are cut to waste less

- Using cnc machines that use less energy

CNC plywood furniture also lasts longer. This means you don’t need to replace it as often. This helps cut down on waste even more. By using green practices, makers can make products that are both good for the planet and high quality.

From Concept to Creation: The CNC Furniture Workflow

Creating custom furniture with a CNC router needs a good plan. It starts with designing and ends with the final product. Design software essentials are key. They help designers make detailed designs, like custom chair plans, with great precision.

When making furniture with a CNC router, planning is key. You need to pick the right materials and set up the CNC machine. Also, you must optimize the cutting process. This way, you can make sure your products are top-notch.

Key Steps in the CNC Furniture Workflow

- Designing the furniture using specialized software

- Preparing the CNC machine for production

- Executing the cutting and carving process

- Inspecting the final product for quality and accuracy

By following these steps and using the right tools, like CNC chair plans, makers can create high-quality furniture. CNC routers have changed the furniture industry. They make it easy to make complex designs with precision.

Market Demand and Business Opportunities

The demand for custom and sustainable furniture is growing fast. People want unique, eco-friendly pieces that show their style. This trend is a big chance for businesses to make money.

One big question is can you make furniture with a CNC machine? The answer is yes. With the right tools and software, businesses can make many custom furniture pieces.

When thinking about buying a CNC machine, another question is how much does a CNC cost per hour? The cost depends on the machine type, upkeep, and design complexity. But, with the right plan, the profits can be high.

Some important market trends and customer groups include:

- More demand for custom, green furniture

- Interest in smart home tech and automation

- More online sales and social media for furniture

- Customers: green shoppers, tech lovers, and businesses wanting unique furniture

By knowing the market and business chances, entrepreneurs can make smart choices. They can invest in CNC tech and create a winning business plan.

Future Innovations in CNC Furniture Technology

The future of CNC furniture tech is bright, with new machines, software, and materials on the horizon. Knowing what is cnc in furniture? helps us see the big potential in this field. It’s key to ask is cnc woodworking profitable? and how it can change furniture making.

Some exciting new ideas include:

- Advanced machine learning to make cuts better and faster

- New materials and textures to open up more design options

- Easier software for designers and makers

As people want more custom and complex furniture, CNC tech will play a bigger part. Knowing what CNC can do helps businesses decide if it’s right for them. This way, they can find new ways to grow and innovate.

Conclusion: Embracing the Digital Woodworking Revolution

CNC techniques furniture is changing the woodworking world. It brings many benefits that are changing how we design and make modern furniture. Woodworkers and furniture makers need to join this digital woodworking movement. It opens up new ways to innovate and grow.

This article showed the good things about CNC techniques furniture. It brings precision and efficiency. It also lets woodworkers make cool designs and use materials better.

The need for unique and new custom furniture is growing. CNC techniques furniture will become even more important. Furniture makers who keep up with technology will do well. They will meet the changing tastes of customers.

The woodworking future is digital. Those who get into CNC techniques furniture will do well. By getting the right tools and learning, woodworkers can start a new creative and profitable time in furniture making.

FAQ

What defines CNC furniture manufacturing?

CNC furniture making uses computer-controlled machines. These machines cut, shape, and assemble wood. This results in precise and detailed designs.

How has CNC woodworking evolved from traditional methods?

CNC woodworking has moved from manual to digital methods. This change brings more accuracy, efficiency, and customization options.

What are the key components of CNC furniture production?

Key parts include design software and CNC machines. Also, material selection and quality control are crucial. They ensure precise and consistent results.

How does the precision of CNC techniques benefit furniture making?

CNC techniques allow for flawless designs and complex patterns. They also enable intricate joinery. This makes CNC valuable in modern furniture making.

What are some essential CNC router techniques for furniture making?

Important techniques include basic cutting and carving. Also, advanced joinery and surface finishing are key. They help achieve the desired look and strength.

How do the costs of CNC and traditional furniture manufacturing compare?

CNC machines cost more upfront. But, CNC is more cost-effective in the long run. It saves on waste and allows for custom designs.

What are the innovative design possibilities with CNC furniture production?

CNC offers many design options. It allows for complex patterns, custom designs, and material optimization. This reduces waste and boosts sustainability.

How can CNC techniques contribute to sustainable furniture practices?

CNC supports sustainable practices. It uses eco-friendly materials and reduces waste. It also uses renewable energy in production.

What are the key steps in the CNC furniture workflow?

The workflow includes design software, production planning, and quality control. These steps ensure high-quality furniture pieces.

What are the current market trends and profit potential for CNC techniques furniture?

The demand for custom, sustainable, and innovative furniture is growing. This creates a promising market for CNC furniture. Businesses can make good profits by meeting customer needs.

What future innovations can we expect in CNC furniture technology?

Future CNC innovations include better machine design and software. New materials will also be integrated. These advancements will expand CNC’s possibilities and profitability.

Source Links

2024’s Top Innovations in CNC Machining

What I Do with a CNC in My Shop | Popular Woodworking

CNC Machining vs Manual Machining: Which Technique Is Best | CNC Precision Machining Service

A Tinkerer’s Guide to CNC Basics | Business & Other | eBook

Technological developments in the woodwork trades – WOOD DESIGNER

Is Digital Manufacturing a Friend or a Foe? – FineWoodworking

From Traditional Craftsmanship To Modern Techniques – FasterCapital

Precision Machining for Your Furniture & Hardware Needs – Colburn Manufacturing Company

The Art of Furniture Making with Precision Milling

Understanding CNC Machining: A Comprehensive Guide

Unlocking the Potential of CNC Designs in Woodworking: A Creative Journey – The Original WorkShop

Woodworking CNC Tools Market Size & Forecast 2025-2035

CNC Machining Excellence | Boost Efficiency – Zintilon

Unlocking the Potential of CNC Designs in Woodworking: A Creative Journey – The Original WorkShop

The Whitepaper of CNC Router | IN3DTEC | Prototyping & On-demand manufacturing services

The Ultimate Guide To Sustainable Furniture: Building a Greener Future

Eco-innovations in wood product manufacturing technology

Revolutionizing Precision: Unleashing the Power of CNC Machines