Architectural millWork: classic features, modern solutions

Architectural millThe detailed wooden shirts, molds and components that define interior spaces have always been around accuracy and elegance. From pouring the classic crown to the modern cover, professional mud workers are assigned to present beautiful and consistent profiles. Today’s stores face a dual challenge: honoring traditional designs while working efficiently with modern materials and tools.

For the record, wainscotting is the panels at the bottom of these walls. The chair rail is the sloping sector above the wainscot, and the base plate below.

For the record, wainscotting is the panels at the bottom of these walls. The chair rail is the sloping sector above the wainscot, and the base plate below.Classic profiles that every mill worker should know

Although the design trends are developing, some features remain essential of the architectural mill work. These shapes are the basis of most cutting packages and restoration projects:

- Pour the crown Wall bridges to the ceiling; The differences include Cove, Ogee Crown and Codedblies.

- Plate – It protects the bottom of the walls; It is usually simple but sometimes detailed with beads or bays.

- Cover / Architrave Doors and windows tires; It can range from simple tours to multi -step designs.

- Railways and railways Originally, functional, and now decorative.

- Paple molds / wainscoting -Determine the wall panels or high panels association.

- Specialization details Beads, cells, ovolos, Roman Ogiz, Philier, and Lamb tongues add great accents.

For restoration work, the ability to match the existing profile can make or break the project.

Modern solutions to create MillWorks profiles

Traditional fishermen and manual routers still have, but today’s mills workers also depend on CNCS and inserting tools for accuracy and repetition. Here is how it fits every professional work course:

Guidance devices

The hand -owned routers with the table equipped with one profile fits remains one of the most direct ways to reduce architectural details. The edge formation is like Ogee, Cove, Roundover, و Pill It is ideal for smaller operation, cut from a store, or custom accents.

Profile parts on CNC routers

Yes, CNC machines He can Give the profile bit. This is useful when you need an Ogee or COVE to repeat on flat arrows. However, most stores prefer other tools for more sophisticated templates, since CNC flexibility comes from tools instead of fixed cutter forms.

Standard CNC tools

The spiral, straight and biblios cuts are real work devices on CNC routers. Through tool positions, operators can “build” almost a dedicated pour profile. This is the way to move to wide crown molds or unique historical copies.

Enter Profile tools

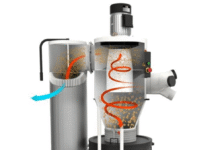

For high size floods, Enter Profile cutters Right. The replaceable knives maintain a decrease in the costs and consistent performance, especially when working with MDF or other detector sheet commodities. It can be used on CNCS or hunters depending on the store preparation.

Professional mastery workers prefer solid carbide incitement such as CNC TRU-Point parts (above) or interchangeable problem-ranging partitions (below), for long-term edges and cost saving.

The Profile Pro ™ profile features more than 135 different patterns of switching steel knife, starting from pouring carpentry into doors, which can all be used with one cutter head. An empty (non -ground) knives are also available for custom patterns.

Problem breakers

Fishermen are indispensable for the large employment of securities profiles. Many stores are still converting to their ability to deal with wide cuts and long production courses – especially when the historical details are widely reproduced.

Which positives use more parties or CNCS?

In fact, most MillWork stores are still highly dependent on problem breakers to operate daily casting.

The housing deals with the wide stock, long lengths, and repeat the personal files easily.

At the same time, CNC’s adoption grew quickly, especially in stores that also build cabinets, wall panels or custom architectural elements.

Many professional stores now run a Hybrid setting: They have standard definition files and work size, and CNCS for specialized jobs or where flexibility is a key. Often the best solution comes to the burden of your store, space, and a variety of personal files that you need to produce.

The panels operate the chain of a simple Ogee game made of a hand and BIT router (above, Amana Tool 54297 Carbide Tabled Base Tableing Oge Edge) to complex profiles created on the problem (below, Amana Sc668 Carbide Thadled 3-Wing Base). Whatever your preferences or tool, you have covered Amana.

الاعتبارات المادية

MillWork is not only related to the profile – it also relates to materials:

- خشب صلب

For a complete, ending appearance, Natural Wood is a traditional material of solid wood such as OAK and Mahogany beautifully. The color of the colorful solid wood crown will add color and warm to any room, and because the material is directed, solid wood allows us to create any pattern we love when using the crown pour parts.

For advice: Use sharp tools to avoid burning signs or tear.

Soft wood

The soft wood crown molds, such as pine or aspect, are often cheaper than high -quality solid wood molds due to the increase in the availability of trees. It is easier to cut and sand from solid wood, and takes an excellent choice for the templates that will be drawn. This is also directed, allowing us to create any pattern we love when using the crown crown bit.

For advice: Soft wood is easily cut but can be crushed under boring tools. They also have more resin than solid wood, which will free your blades faster.

لوح متوسط الكثافة

MDF crown (wood -based material uses wooden fibers with industrial resin) is another non -expensive alternative to homeowners and contractors to add beauty to the home. MDF will not be divided into cutting, easy to cut with MITER saw blades, and resist counterfeiting and can be drawn with any high -quality oil or latex coating, making it one of the most diverse pouring types of crown in the market today.

Professional advice:MDF is common in painted pieces. It requires sharp or durable cutters or tools due to depression.

Polyurethan

This crown pouring this weather, scratching and corrosion, which makes it one of the most darkening types of crown pouring. However, it is generally manufactured in white and will not carry the paint or stain for a suitable finishing.

flexible

When you find yourself displayed at an entrance or curved window, the above options will not help you complete the project of you. Therefore, there is a flexible crown, which will not be broken or divided, which makes it easy to decorate windows and curved entrances. Flexible tool is one type of polyurethane, which consists of polymer resin, which is designed for curve and bending around shapes, unlike a 90 -degree angle.

Aluminum, copper and steel

It is often used in sealed metal crown deals, characterized by hard construction of the hard service available for use as a decorative accent. It is formed inside and outside the angles eliminating the miter pieces, which makes the installation easy. It is easy to cut the saws of the saw steel pieces, and install like traditional molds. It can also be used in retail spaces, workshop, fertilizers, kitchens, offices and commercial exhibitions.

The feeding rate, tools, and chips’s evacuation play a major role in producing clean results, regardless of materials.

Tips for mills

Current identification files match By creating molds or scanning using the CNC for restorations.

Use dances and fences To keep consistency through multiple pieces.

Choose tools by operating volume– Stock routers for short operation, inserting production tools.

Mind safety When using large profile cutters; Always use the right and speed guarding.

Toolstoday solutions

In Toolstoday, we store a wide range of architectural and architectural guidance parts of the Amana tool, along with CNC tools and problem cutting for each type of MillWork applications. For production environments, we have Enter Profile tools It provides long -term performance and an easy knife replacement.

خاتمة

The architectural Millwork continues to combine traditions and innovation. By understanding classic definition files and choosing the appropriate modern tools – whether it is the router, problem, cnc, or cutting the cutter – professional mills workers can achieve immortal results with today’s efficiency. The correct tools not only cut the wood – it helps in forming the area of space.